주)페트로산업 메인 네비게이션

페트로산업 sub navigation

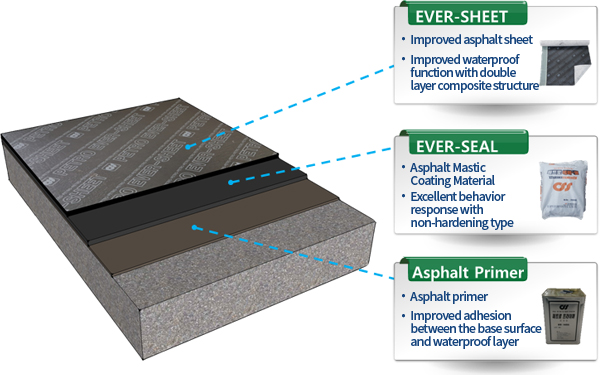

PETRO EVER-SEAL

|

Overview of Technology

|

Types of Product

|

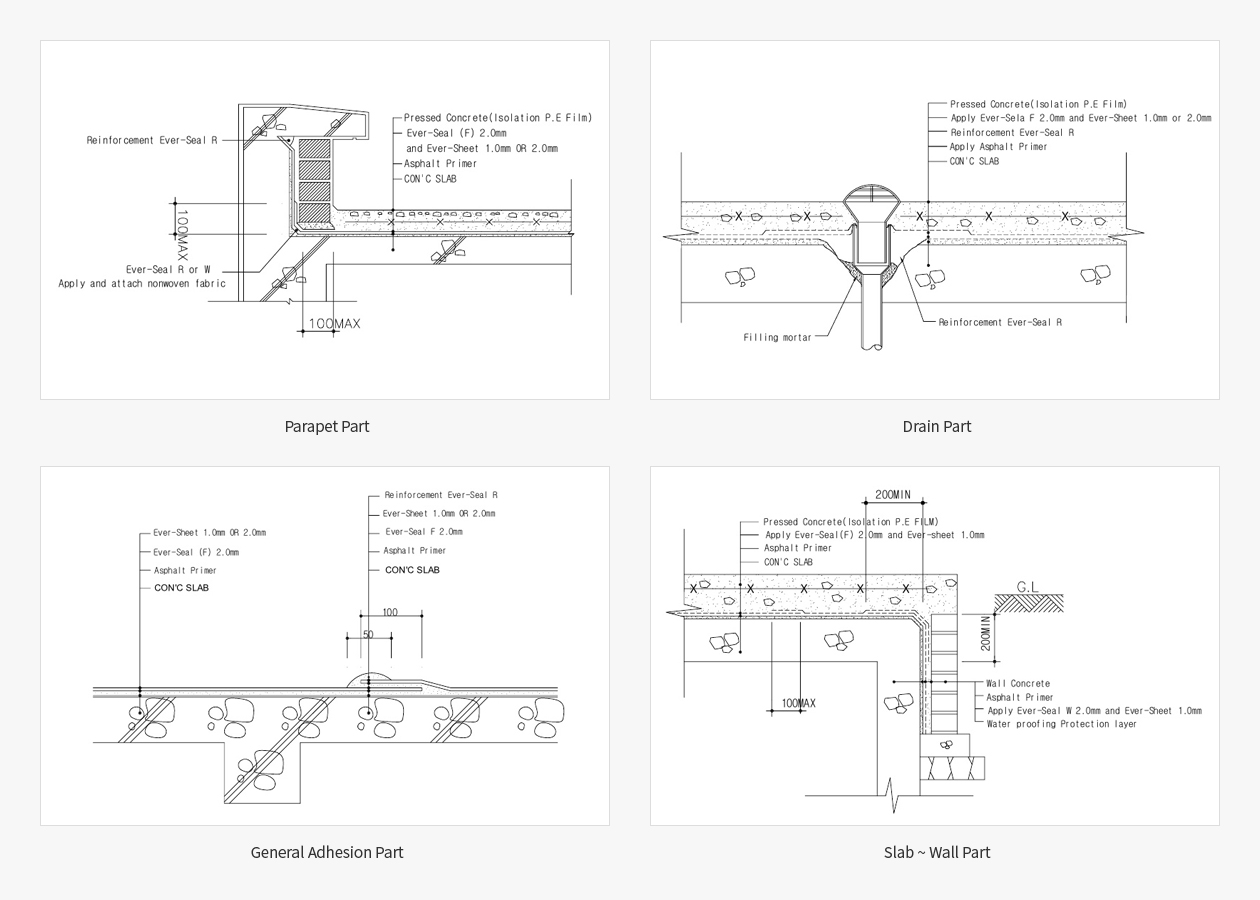

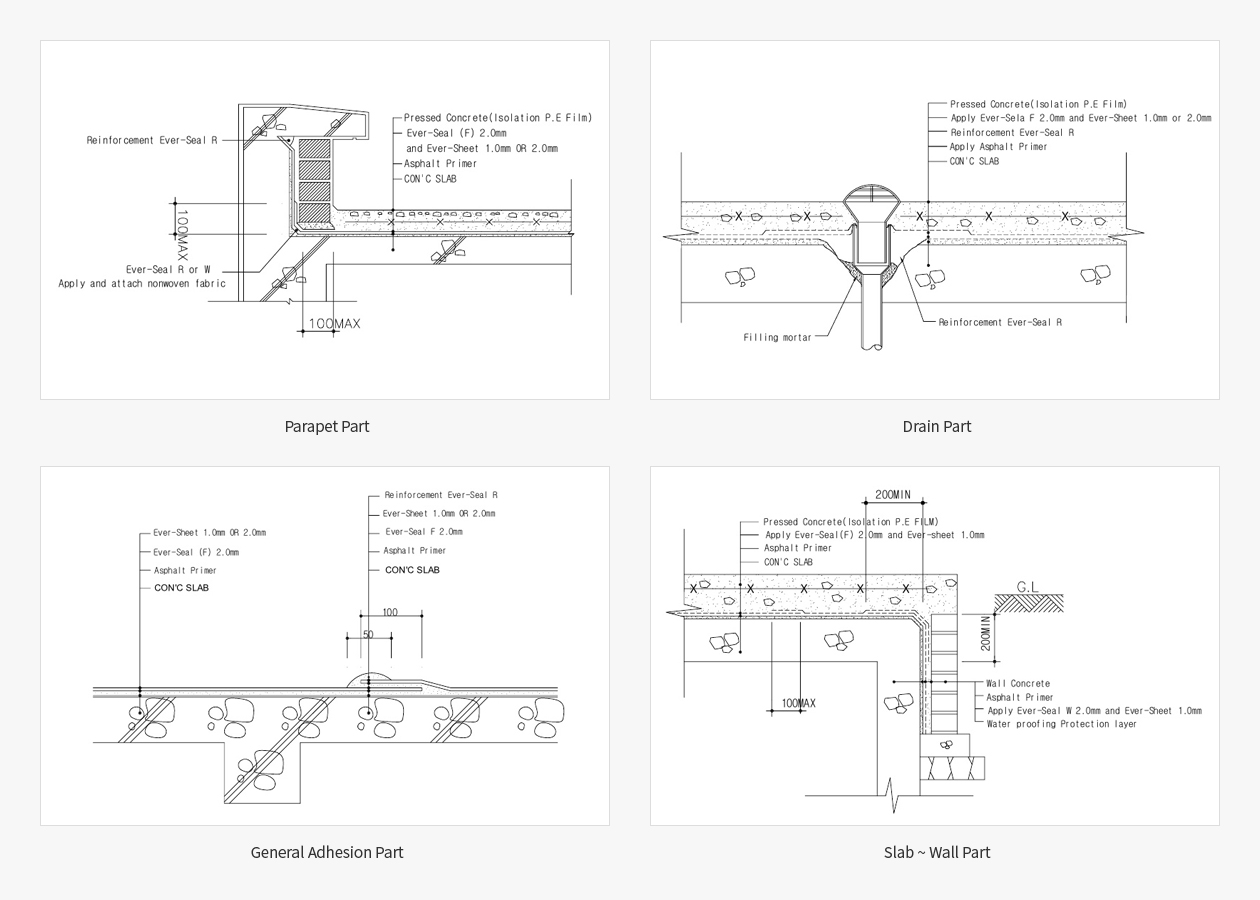

Construction Floor Plan

Packaging Unit

| Product Name | Product Photo | Packaging Unit |

|---|---|---|

| Primer |  |

18ℓ |

| EVER-R (For Reinforcement) |

|

20KG |

| EVER-W (For walls) |

|

20KG |

| EVER-F (For floors) |

|

20KG |

| EVER-Sheet |  |

Thickness : 1~2mm Width : 100cm Length : 10~20m |

| EVER A+ Sheet |  |

Thickness : 1~2mm Width : 100cm Length : 10~20m |

Quality Standard

- LH 42531 (2011) : Rubber Asphalt Double-layered Waterproof

| Item | Quality Standard |

|---|---|

| Solid (%) | Above 70 |

| Dissolvement (%) | Above 15.0, Below 30.0 |

| Flow Resistance | 3 sheets all have flow length of below 3.0. No wrinkles. |

| Alkali Resistance | No Problem |

| Heat Resistance (60℃) | No Problem |

| Low-temperature Curve (-15℃) | No Problem |

- KS F 4917 (2016) : Improved asphalt waterproof sheet

| Classification according to use | Non-exposure multiple layer waterproof | |||

|---|---|---|---|---|

| Classification according to material composition | TYPE A | |||

| Tensile Performance | Tensile Strength (N/㎜) | Untreated | Above 5.0 | |

| After heating | Above 80% of untreated test value | |||

| After soaking alkali | ||||

| Coefficient of Expansion (%) | Untreated | Above 15 | ||

| After heating | Above 80% of untreated test value | |||

| After soaking alkali | ||||

| Tensile Product (N·%/㎜) | Untreated | Above 200 | ||

| Tearing Performance (N) | Above 20 | |||

| Heat Resistance Performance | Roll Down Length (㎜) | Below 5 | ||

| Appearance | Will not roll down or shoot out. | |||

| Fatigue performance | Will not rip, crack, or be blocked | |||

| Dimensional stability | Change Rate of value (%) | 0.0±1.0 |

||

| Appearance | No creases, bending, or detachment between layers | |||

| Joint Performance (N/㎜) | Above 4.0 or above 70% of untreated tensile strength | |||

| Pitting Performance | No Hole | |||

Construction Method

1. Cleaning up the Base

2. Apply Primer

3. Reinforce the vulnerable parts

4. Apply PETRO EVER-SEAL

5. Attach PETRO EVER-SHEET

6. Reinforce PETRO-EVER-R |

|